Our survey finds that only a small minority of companies feel ahead of the curve in adapting R&D to the digital world. Here's how to get started on a digital R&D transformation.

Digital technologies are changing not just what products can do, but also how they are designed—and how companies manage and support their development. As more product features move from hardware to software, customers enjoy more-capable products and develop a profoundly different ownership experience. The capabilities of a product are no longer fixed at the start of production: new features can be added over time through software upgrades. That evolution is encouraging product companies to adopt the feature-based development approach pioneered in the software sector, with development work continuing throughout the product lifecycle.

Digital technologies also enable companies to offer new services alongside their products. Sensors built into vehicles or manufacturing equipment can spot tell-tale evidence of mechanical problems, allowing predictive maintenance interventions. Black-box data recorders in cars let insurance companies adjust their prices according to the way the vehicle is driven.

Some major players and smaller manufacturing companies have responded to digitization by building their own ecosystems of products and associated services, or by collaborating with others to do so. GE is incorporating its Predix cloud-based data analytics platform into many of its offerings, for example, while German machine tool company Trumpf has launched AXOOM, a platform for internet-connected machines and related applications. An automotive consortium involving Audi, BMW and Daimler purchased mapping software company HERE from Nokia in 2015.

Design and development tools are changing too. Companies can build and test detailed virtual models of their designs, allowing them to evaluate multiple design options and identify and resolve issues before any prototype hardware is manufactured. In the automotive industry, the use of such virtual prototyping techniques has helped to cut the time required to develop a new vehicle from 36 months to 24 months since the 1990s. Artificial intelligence techniques are helping designers and engineers find better solutions to difficult trade-offs and optimization problems. Airbus used a technique that mimics bone growth in animals to develop a 3D-printed wall for aircraft cabins that weighs 55 percent less than the conventional design.

By collecting and sharing data on the progress of R&D projects, companies are transforming their performance-management processes. Managers can now use digital dashboards to rapidly identify concerns or opportunities and to improve review and decision making. At consumer goods company P&G, for example, more than 50,000 employees have access to a "decision cockpit" that combines multiple sources of business data into a single, accessible format. The company has also built digitally-enabled meeting rooms where data is shown on multiple large screens to facilitate group review and decision making.

Digital technologies create opportunities for incumbents in R&D-intensive sectors, but they also suggest real potential for disruption. Other long-established businesses have already been transformed by new digital players: by streaming services in music, ride-sharing platforms in transportation, and rental-property marketplaces in hospitality. New players are emerging in the automotive and industrial sectors too, suggesting these industries cannot afford to be complacent about the digital threat.

Survey says: not yet ready

Respondents to our "R&D of the future" survey1 were clear about the significant role digitization will play in the future of their industries. Most of the chief technology officers (CTOs) we surveyed believe digital technologies will have a pivotal impact on future R&D activities, for example. But their self-reported level of readiness is low. Even in the sector that considers itself best prepared—machinery and industrial equipment—only 26 percent of CTOs said they were confident about the trend. In the automotive sector, just 4 percent of CTOs said the same.

We also saw significant variations in readiness by company, region, and role.

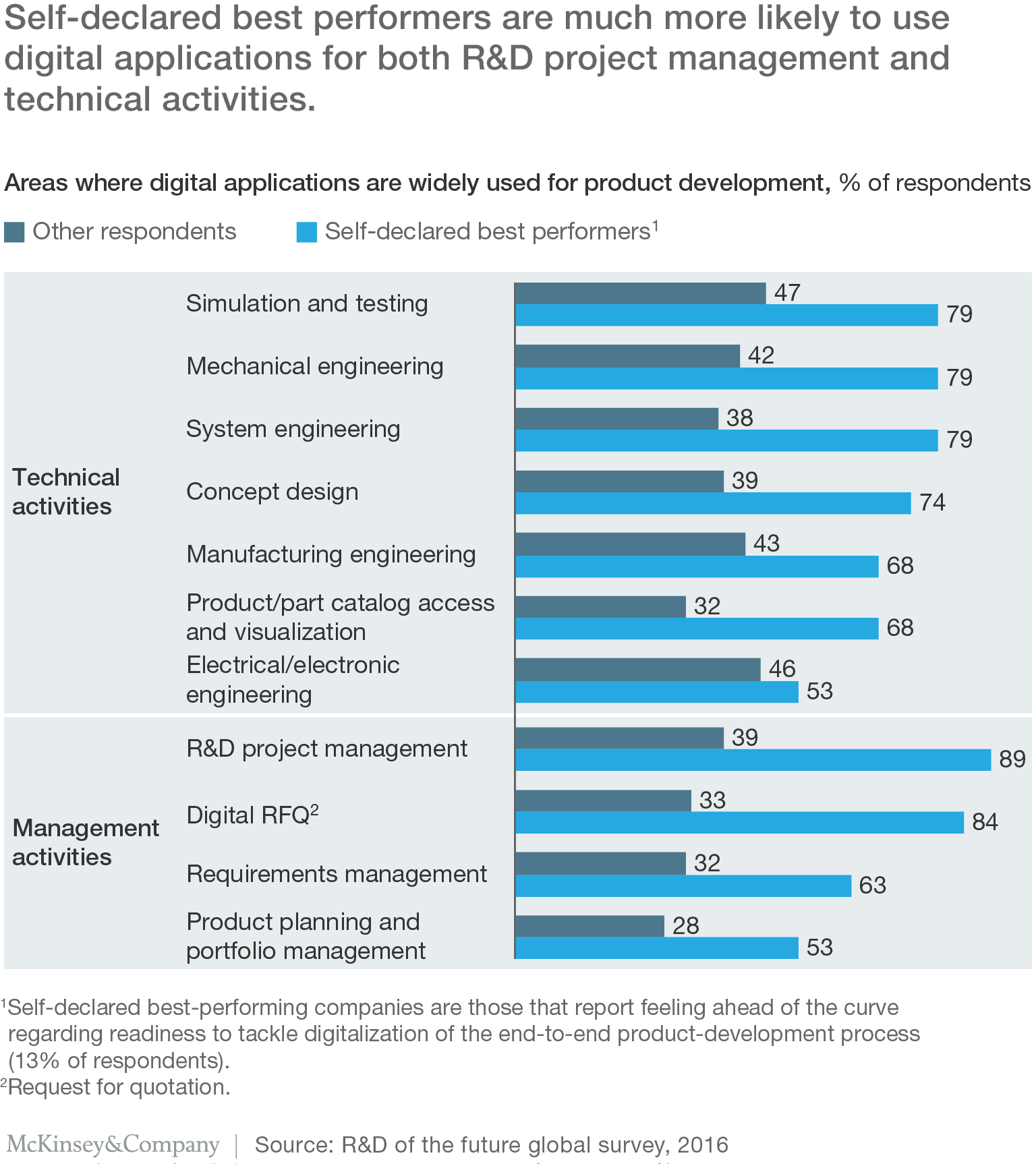

When we asked in more detail about the use of digital applications in specific R&D activities, several telling differences emerged between self-declared front runners in digitization and other respondents. Unsurprisingly, front-running companies were more likely to use digital tools at every phase of the R&D process. The largest differences, however, arose in the use of digital tools for management activities like planning and project management. While other respondents were more likely to use digital technologies for technical activities than for management, front runners showed a very different pattern (exhibit).

Overall, front runners were twice as likely to use digital tools for both technical and management activities as other companies. Leading companies were particularly likely to use product data management (PDM) and product lifecycle management (PLM) systems, citing the benefits such systems provide in reducing both product and development costs.

When we asked respondents to highlight the main roadblocks preventing them from making the transition to digital product development, four main factors stood out. First was management mind-set, with managers either believing (mistakenly) they already have all the necessary capabilities in-house or being reluctant to make the leap to untried and potentially incomplete new approaches. Second were organizational and cultural issues, especially the concern that digitization would further burden R&D staff already struggling to fulfill their basic mission. Third, companies cited a lack of capabilities, especially the skills required to manage big data or develop new digital tools. Finally, some companies expressed a reluctance to make what they see as large investments in unproven technologies, or where standards have yet to emerge.

Self-declared best performers in our survey have adopted specific management practices to address some of these challenges. Some, especially in the US, have appointed a chief digital officer (CDO) responsible for company-wide digital strategy. Other significant practices include the development of external partnerships, the recruitment of experts from other industries or sectors, and the creation of a digital-strategy road map to guide investment decisions and change planning.

Enabling the digital R&D transformation

We believe that digital product development is a transformative journey and needs to be managed as such. That calls for all the elements of an effective transformation, including senior leadership commitment, a clear vision and road map, and processes for the fast piloting and deployment of new working practices.

Digital transformation also requires some changes that are specific to product development. In particular, companies need to upgrade three aspects of their current R&D ecosystem: product definition; core processes and tools; and performance management.

Product definition

As software features can be updated at different stages of the product's postpurchase life, building (and rebuilding) business cases does not end once the sale is made. Business cases should be updated to incorporate the additional cost and revenue generated by updates.

As the purchase, support, and operation of products increasingly occurs online, companies must take advantage of new forms of interaction with customers to gather requirements and insights, for example through consumer reviews and social-media conversations.

And as more software is integrated into products, the R&D team capabilities must evolve. Software engineers, for example, will need a wider range of expertise beyond coding, including algorithm development, database management, and advanced analytics.

Core processes and tools

Engineering project plans will need to accommodate feature-based development, with feature road maps that separate the delivery of specific features from the development of the underlying hardware—and that extend to postsale product upgrades as well.

Core engineering processes must change to take advantage of innovative new tools, such as the automation of repetitive tasks (like writing test protocols), the application of artificial intelligence techniques to optimize designs around tight constraints, and the seamless sharing of digital product information between internal teams and external suppliers.

Performance management

To transform its R&D performance, a company must first understand it. New digital tools can enable far more transparent measurement of product-development efficiency, productivity, and effectiveness. Cloud-based R&D dashboards, for example, let top management make fact-based, financially sound project decisions at the concept, development, and sales phases of the product lifecycle. At some companies, advanced analytics and artificial intelligence techniques are automatically extracting insights about how R&D projects and development teams are performing, using data sources ranging from project and financial records to email traffic.

The authors would like to thank Florian Weig for his contributions to this article.

About the authors: Elia Berteletti is an associate partner in McKinsey’s Taipei office, Guillaume Deraisme is a consultant in the Montréal office, and Thomas Morel is an associate partner in the Lyon office.

1 Survey conducted from May to August 2016; 200 qualified respondents (R&D leaders and experts) from North America, Europe, and Asia participated, of which approximately 40 percent were CTOs or equivalent.